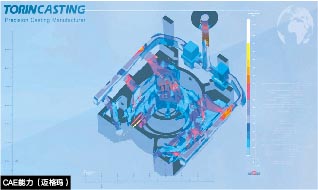

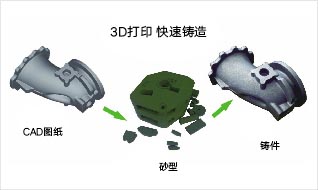

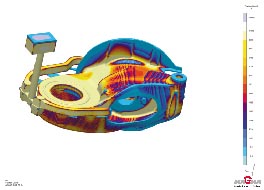

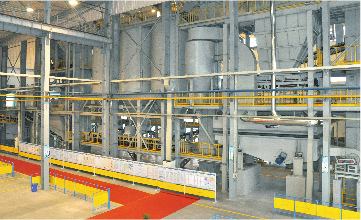

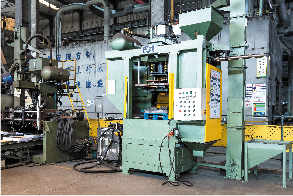

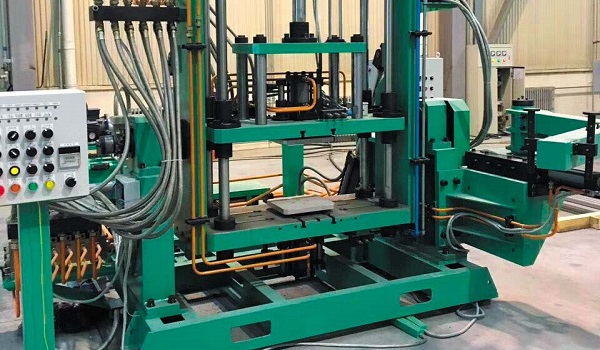

The technical construction material center was built to invest more in product development and technological innovation, and meet the CAD and CAE capabilities required for independent R & D. We introduce the world advanced MAGMA simulation analysis software to reduce design defects, and improve the casting quality to do the improvements and innovations on the casting’s manufacturing and machining methods . We can offer low volume prototypes and design for manufacturing service.